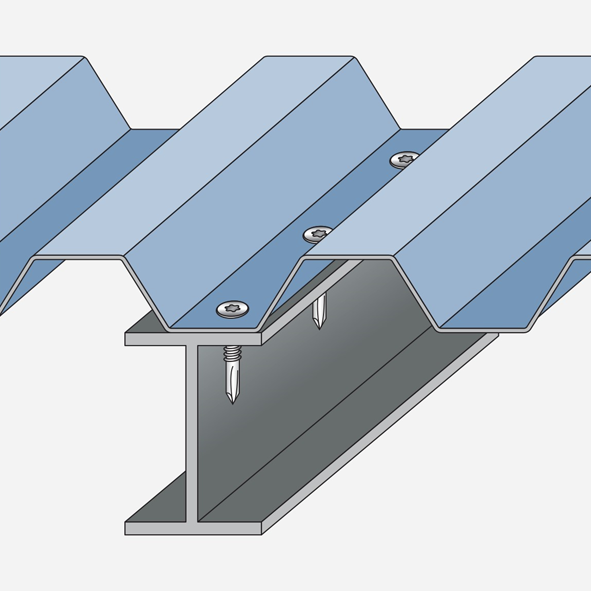

Stainless Steel Countersunk Sheet to Heavy Section

For fixing sheet to hot rolled purlins (4.0mm – 12.5mm steel).

| Part Number | Length (MM) | Diameter (MM) | Drill Point |

|---|---|---|---|

| 40.5SSC | 40 | 5.5 | No. 5 |

| 60.5SSC | 60 | 5.5 | No. 5 |

| 80.5SSC | 80 | 5.5 | No. 5 |

Heavy section screws fasten sheet metal to hot rolled purlins (4.0mm – 12.5mm steel).

- Stainless steel provides excellent corrosion-resistance which increases the life-span of the fixing.

- Countersunk heads lie flush with the profile, and require T-25 bits.

- The fine thread provides many points of engagement with the purlin, maximising pull-out values.

- The no. 5 drill point is designed to ensure a clean cut through up to 12.5mm steel, without burn-out.

For maximum fastener performance, we recommend using a tek screw driver which does not exceed 2500RPM.

| 40.5SSC | 60.5SSC | 80.5SSC | |

|---|---|---|---|

| A (mm) | 9.90 | 9.90 | 9.90 |

| B (mm) | 40.00 | 60.00 | 80.00 |

| C (mm) | 25.00 | 45.00 | 65.00 |

| D (mm) | 5.50 | 5.50 | 5.50 |

| E (mm) | 15.00 | 15.00 | 15.00 |

| F (mm) | 5.00 | 5.00 | 5.00 |

Click ⭳ to download Technical Data Sheet

| 40.5SSC ⭳ | 60.5SSC ⭳ | 80.5SSC ⭳ | |

|---|---|---|---|

| Pull Out (kN) - 4.0mm S275 Steel | 8.90 | 8.90 | 8.90 |

| Pull Out (kN) - 6.0mm S275 Steel | 9.50 | 9.50 | 9.50 |

| Pull Out (kN) - 8.0mm S275 Steel | 9.50 | 9.50 | 9.50 |

| Pull Out (kN) - 10.0mm S275 Steel | 9.50 | 9.50 | 9.50 |

| Pull Out (kN) - 12.0mm S275 Steel | 9.50 | 9.50 | 9.50 |

| Shear (kN) | 8.77 | 8.77 | 8.77 |

| Tensile (kN) | 11.49 | 11.49 | 11.49 |